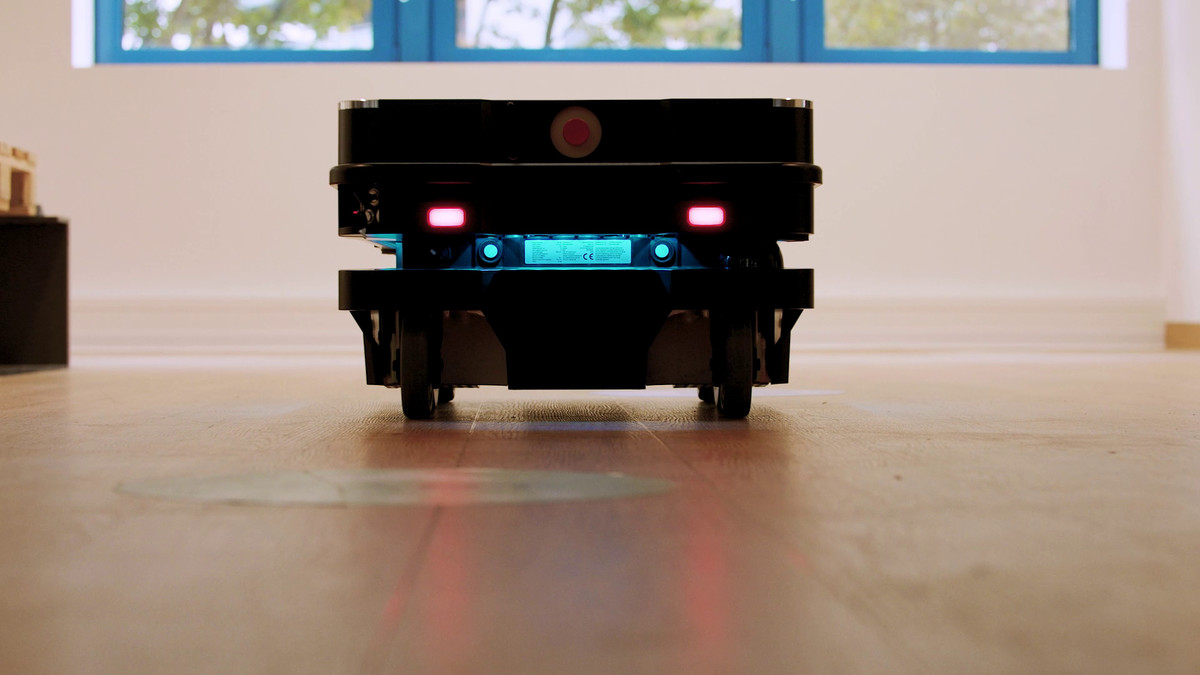

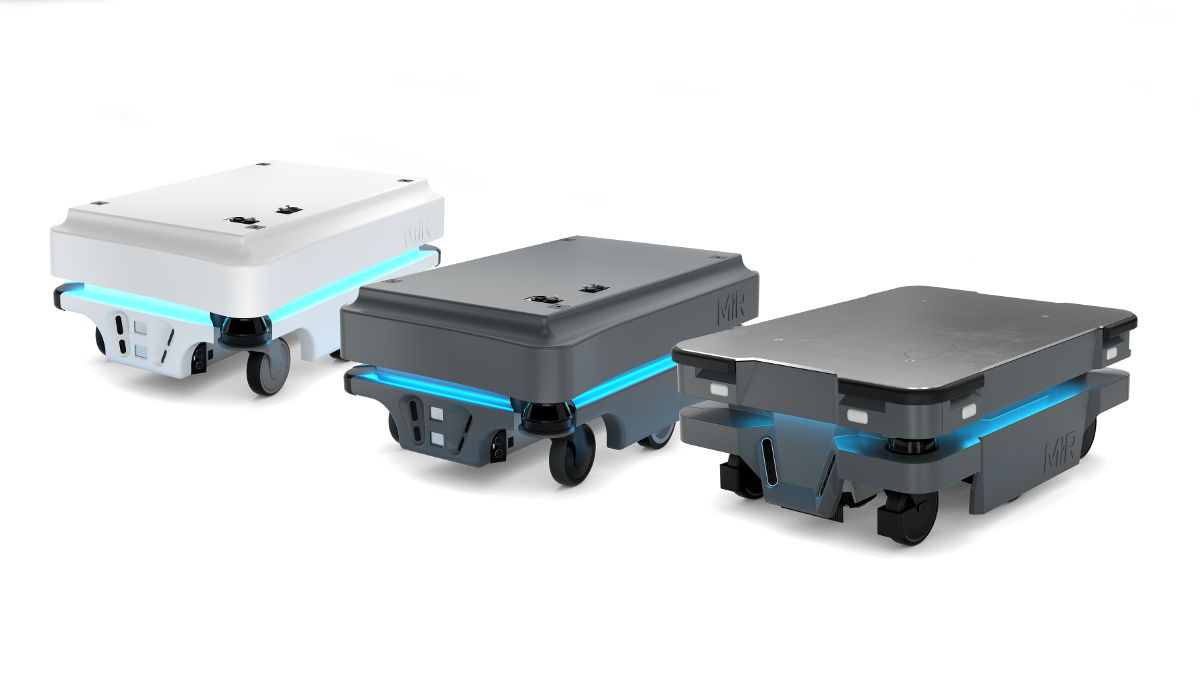

Die autonomen mobilen Roboter von MiR setzen genau hier an. Sie bieten durch ihre benutzerfreundliche, webbasierte Programmiertechnik, die für den Einsatz in KMU notwendige Flexibilität und Skalierbarkeit. „Wir haben die Idee zum Prinzip erhoben, dass die Endkunden selbständig von uns und unseren Partnern Programmänderungen selbst vornehmen können, um die Roboter in sich verändernden Umgebungen zu betreiben“, erklärt Jörg Faber, der als Sales Director am Standort in Eschborn (bei Frankfurt a. M.) die Geschäftsentwicklung von Mobile Industrial Robots (MiR) im DACH-Raum und den Benelux-Staaten verantwortet. „Unsere Kunden können so die Roboter auch in Umgebungen einsetzen, die sich durch die Umstellungen von Maschinen und Produktionsweisen quasi von jetzt auf gleich ändern.“

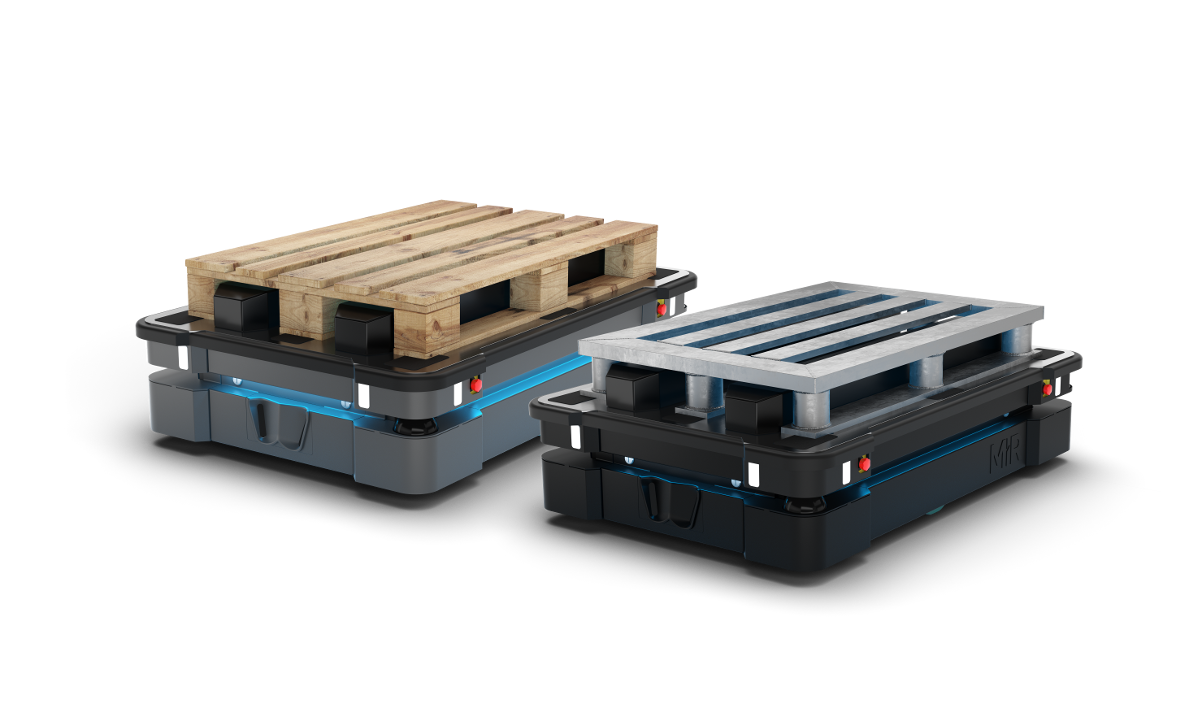

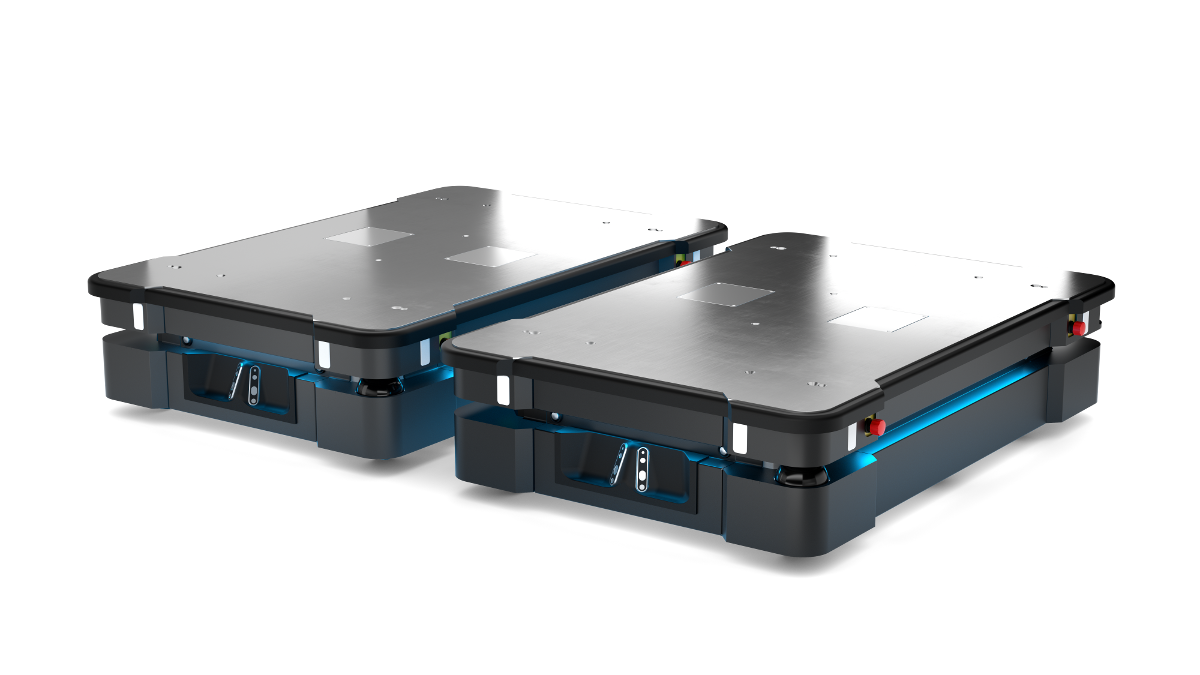

Die AMR von MiR verfügen über feine Sensoren, die Hindernisse und Personen erkennen und umfahren und auch Menschen identifizieren und somit Kollisionen vermeiden. Je nach Modell tragen sie Lasten zwischen 100 und 1350 Kilogramm. Sie lassen sich damit für nahezu alle Anforderungen der Intralogistik einsetzen, vom Materialtransport aus dem Lager in der Montage über Transporte innerhalb der Montagelinie bis hin zu Bereitstellung der produzierten Waren für den Versand.

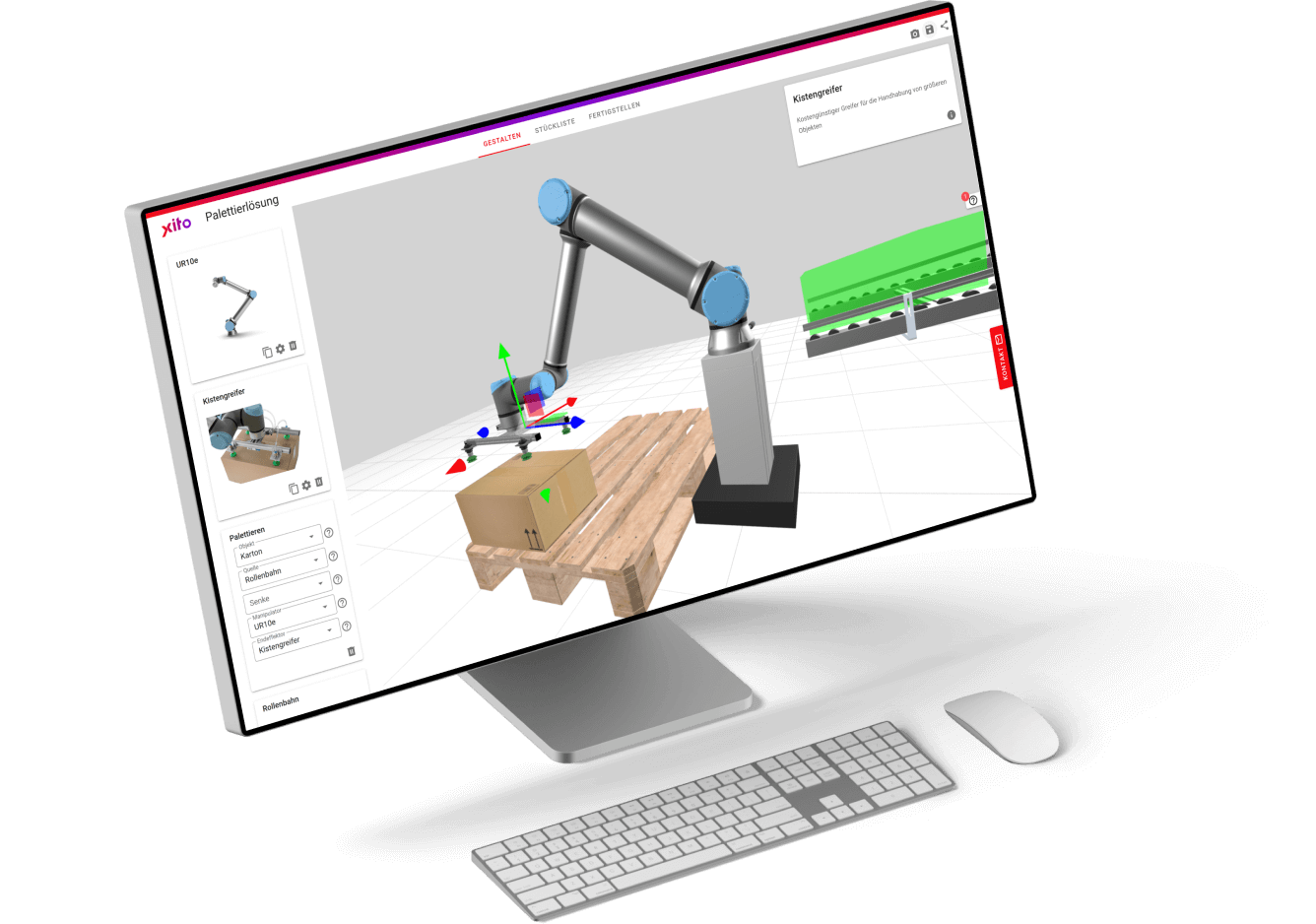

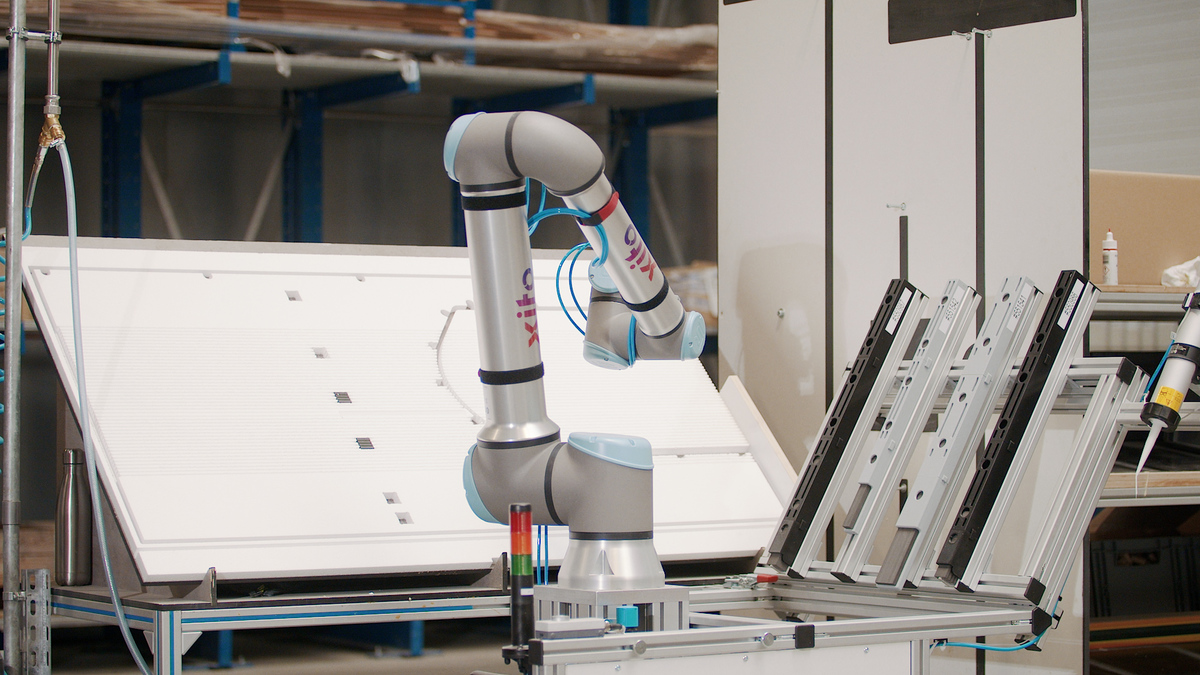

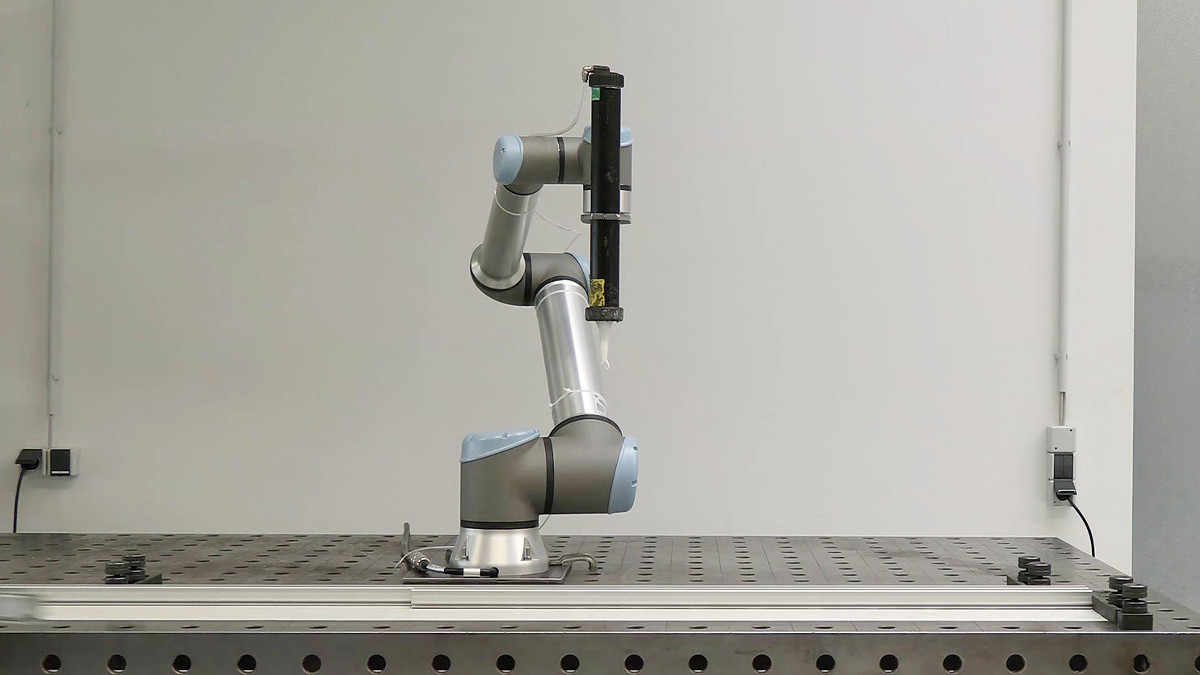

Die Einbindung der MiR-Roboter in das XITO-System erleichtert die Individualisierung von automatisierten Transportlösungen auf Basis von MiR-Modellen. Auf der XITO-Plattform finden Anwendende Lösungsbausteine, die sie mit den AMR von MiR kombinieren können. Damit gelingt beispielsweise die Integration der mobilen Roboter in das übergeordnete Warenwirtschaftssystem ohne hohen Programmieraufwand. Auch die Kommunikation mit Maschinen und/oder die Kooperation mit stationären Robotern lässt sich über die Plattform einfach umsetzen. Ein Beispiel dafür bietet die XITO-Success-Story zu Daimler TSS. Im dort beschriebenen Use Case stapelt ein stationärer Roboter Kartons, die dann von einem autonomen Transportroboter von MiR übernommen und an ein Etikettiersystem überführt werden. Besonders für Lösungsanbieter ist die Kombination der MiR-Roboterbasis und Erweiterung über das XITO-Baukastensystem ein Plus.